Glazing your pottery is too much fun. It gives your pottery a nice look and effect, along with a very durable attire. But it is enough to ruin your fun if glazing is not done correctly. A glazing mistake, flaking, or egg shelling of glaze is enough to give you hard times with your pottery glazing.

But have you ever thought about why your glaze keeps flaking or eggshells off? Though glazing is highly experimental and gives you the fun to create something new, it is not at all an easy task that anyone can do. Glazing comes with various complications that need to be checked on while proceeding with the process. Or else it will give you the results like flaking off or eggshells of your pottery glazing.

In this article, we are going to talk about why your glaze keeps flaking or eggshells off. Read on to know more.

Glaze flaking off or shivering:

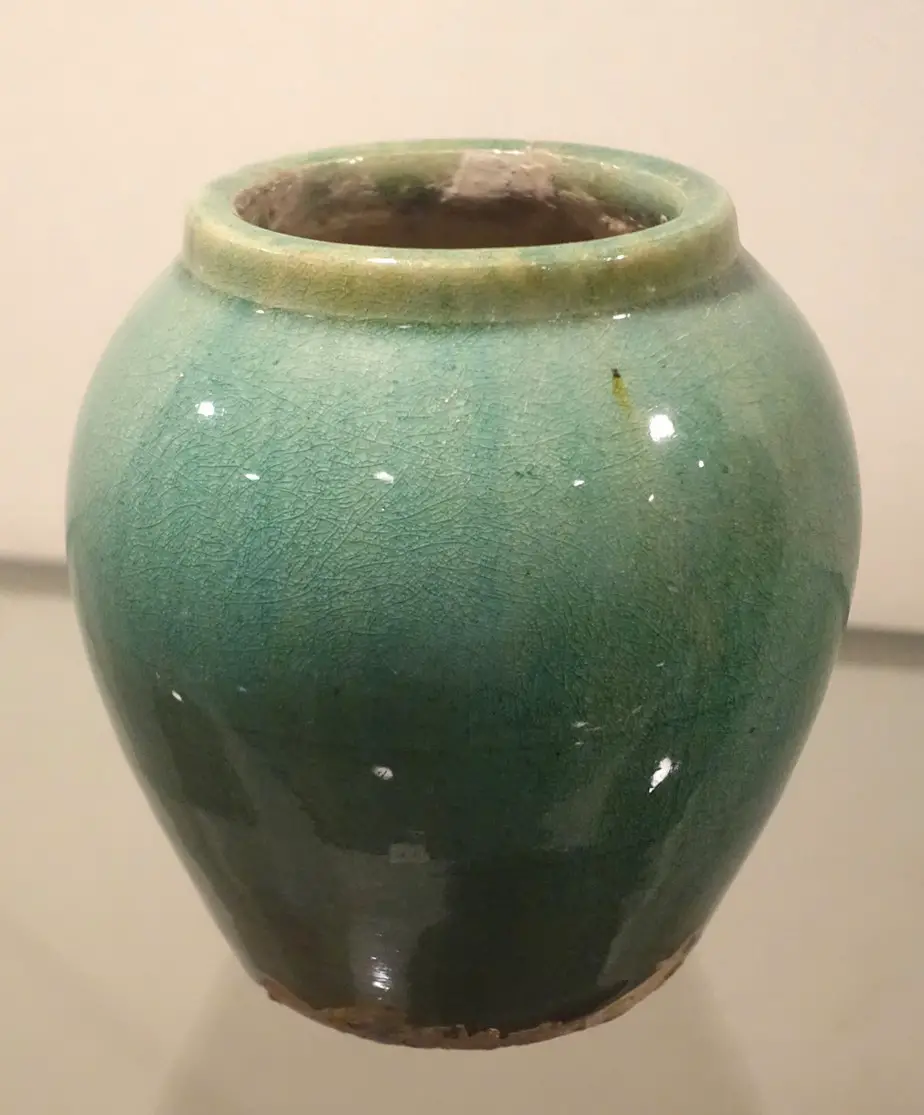

Shivering is one of the most common kinds of ceramic glaze defects that makes the glaze flake off. The peeling off of the edges of the ceramic ware leads to the coming out of the glaze, which is highly recognized as a significant glazing mistake. The main reason behind shivering is too much compression due to thermal imbalance. The shivering of the glaze can be more clearly described when you can see that the painting is chipping off from the clay surface or the body.

Shivering thus leads to the tearing or breaking off of the underlying clay body, which leads to the cracking of the whole pot. Shivering is characterized as the opposite of crazing. There are a lot of reasons that work behind influencing the shivering on the clay body. However, knowing about the reason lets you understand and correct your glaze’s flaking or eggshell problems.

The confusion between shivering and crazing tends to happen. Here is how to differentiate.

Glazing mistakes |

Characteristics |

Shivering |

Flaking off of the glaze from the surface, edge, or rim area |

Crazing |

Crazing or shrinking of the glazing leads to uneven surface |

So now, here are the various reasons that are responsible for the shivering of the glaze.

Thermal expansion:

Thermal expansion works as a common problem for the glazing of your pottery. It is less likely common to happen due to the higher thermal expansion of the glaze. The fired glaze that wants to flake off from the clay surface and edge area happens due to the wrong matching of the thermal expansion in the body and glaze area.

Most of the time happens when the glaze acquires a higher thermal rate than the clay body while firing. The main reason behind this is the tolerating power goes under the compression, which creates tension in the area. While the clay body goes under pressure inside a vessel, it automatically gets a force that ruins the glazing structure.

Unimproved body-glaze interface:

In case the body of your pottery and the glazing is not improved correctly, it leads to over-compression of the glaze. This excess compression leads towards the release of the glaze from the surface area and edges. The main reason behind this problem can be the low firing range of the pottery glaze, which impacts the glazing’s longevity.

At the same time, another reason can also be the usage of the slips under the glaze. In case you use the engobes or slips under the glaze, it leads to an improper range of flux. The problematic range of flux leads to the weak adhering of the glaze to the body, which develops the problems like flaking off easily. It hampers the bond of the glaze on the clay surface, which leads to a complete failure.

Maintaining a continuous low firing temperature:

The low firing temperature can impose various issues. However, the low firing temperature improves the balance when the clay and glaze interface is not developed together. However, it sometimes increases the compression rate, which leads to such issues.

Various low-temperature clay bodies possess extra talc for increasing the thermal expansion rate. It is usually done to prevent craziness. However, the main drawback is it works as one of the main reasons for shivering.

Improper adjustment of glaze:

In case you like to make your glaze mixture, you need to be very cautious about it while mixing it properly. An adjustment of the base glaze is required to ensure the proper fitting on the clay surface. If shivering occurs on the clay’s proportion for a higher expansion, then it may have happened due to the lack of

frit.

Also, if there is not much adjustment or balance for the talc supply, it can weaken the glazing surface. In case you are using a small amount of talc, pyrophyllite will lower the overall expansion. On the other hand, too much talc increases the expansion too much. Use a moderate amount that ensures the balance.

Abrupt reduction from higher temperature:

The sudden higher temperature reduction can be another problem for this prevalent glazing mistake. In case the high temperature with the reduction range starts burning down the stoneware to brown, it will work as the main reason for the glaze flaking off.

The variation of the warm colors and the body is based on the range of vitrification. Thus, the improperly developed surface area will affect the glazing interface for the porcelain and stoneware. It happens due to the excessive compression that weakens the glazing on the clay surface, which eventually shivers off. For the expansion resistance, you need to control a very moderate amount of properly maintained firing range.

High quartz content may be the problem:

In case the glazing has higher quartz content in the glaze for the stoneware bids, it will bring in the problems like flaking off of your glaze. Usually, those ceramics built with fire clay and ball clay with added silica on the top imposes various issues.

Too much quartz content present in the body discourages the flux rate. Thus, the expansion rate starts being uneven, making the glazing not adhere appropriately to the clay body’s top. On the other hand, this problematic range of glaze infusion is the main reason behind the glazing-related problems.

A bad firing cycle:

The usual range of the clay body firing situation should have a higher thermal expansion with more increased thermal contraction than the applied glaze. It happens correctly when the glazing is put under compression while cooling inside the kiln. It helps increase the durability of the ceramic ware and, at the same time, prevents the glazing from crazing.

A higher temperature ensures proper compression, which is acceptable to tolerate and increases the strength while reducing crazing. However, the situation gets worse when you don’t know how much higher the expansion should be. The improper testing or the wrongly calculated firing cycle leads to the shivering of the glaze. The nonuniformity in the firing range leads to an uneven range of compression and expansion, hampering the result.

Using one slip for all clay bodies:

In case you go for choosing that one slip for all body solution, you may be wrong. The flaking off or the shivering through the rim of a low-fire terracotta can happen if the slip is not proper. Not all the slip goes in sync for all the glaze ranges. In case the slips are not drying properly, it will lead to firing shrinkage and thermal expansion.

Using improper engobe hampers the bond with the glazing, making the body fragile in the low firing condition. The slip that improperly fits the particular type of glaze, clay body, and temperature tends to compromise the glaze’s adherence to the surface area.

Excessive compression range:

In case the glaze goes under the excessive compression range, it can merely lead towards the flaking off of the engobe, which is eventually going to make the glaze come off. If the engobe is not melting correctly, it will enhance the compression range of the body.

Low quartz rate:

On the other hand, the shivering on the rim of the ceramic comes up due to the low quartz rate with a vitreous body that has a lower expansion than the thermal expansion. In case the ceramic is not having the proper amount of quartz, it will impose too much compression that can shiver off the glaze by itself near the edge or rim area. In the case of the lower expansion, which is exerted due to the addition of slip for compression, it will also call upon the entire glazing results’ failure.

How do you solve this problem related to flaking off of the glaze?

Shivering is known as one of the prevalent glazing mistakes that ruin your pottery. However, you can quickly fix this one using some of the proper methods. Maintaining the proper adjustment with the glaze recipe and the clay body recipe serves the expansion range’s uniformity. It helps in preventing shivering-related problems. Here is how you can maintain the proper techniques to prevent the glaze from flaking off:

Proper cooling of the clay and glaze:

The main problem of improper expansion happens when you refrain from your glazed ceramic ware from the proper cooling rate. To overcome life-shivering problems, you need to ensure that the clay and glaze have a compatible cooling rate. The glaze must come at a slight compression rate while cooling. As you are done with firing, don’t instantly open the door of the kiln. Instead, wait for some more time to let the kiln become cool. Then remove the pottery from the kiln.

Ensure a proper glazing recipe:

The glazing recipe and the clay recipe need to be appropriately adjusted to ensure that you have the proper glazing range. Make sure there is not too much silica in the clay body. Also, hold yourself back from using the fine grog silica in the glazing mixture. Decrease the lower expansion materials from the clay body. Add the high expansion materials instead in the clay body.

Here is what you can add and decrease to ensure a proper recipe for glazing.

Balancing the material |

Measurement |

Adding potash feldspar to the glaze |

10-15 parts |

Decreasing flint in the glaze |

5-10 parts |

Add frit or feldspar |

As per requirement |

Adding alkali-based material |

5/10/15 parts |

Reducing flint in the clay body |

5-10 parts |

You can use ready-made glazes, like AMACO Potters Choice Lead-Free Glaze Set, for good results.

Ensure a good firing cycle:

While firing, make sure you are opting for an optimal range of firing cycles. A poorly controlled firing cycle is going to ruin the entire glazing result. Check on the maintenance of the proper cone range. Also, you need to take note of what firing range is recommended for the particular type of clay or the glaze you are using.

Do not use too much talc for a lower firing range:

Using too much talc for the lower firing range leads to the over-expansion of the glaze. It must not be encouraged in case you want to control the proper surface of the glazing. Ensure you are not using a large amount of talc in the clay or glaze while opting for a low firing range. Try to keep it moderate. Also, make sure the talc content is not too low, or else it will give reasons to form crazes.

Conclusion:

While glazing your pottery surface, you need to ensure that you are using the proper amount of glazing with the right firing and temperature range. The problem may also occur if you are using too thin glazing or a contaminated one. Maintain a neat and clean process while glazing your pot and maintain the proper application style.

Also, take note of the recommendations that come with the packet glazes if you’re using one. Therefore, it is vital to ensure that the mistakes mentioned above are not attempted. Otherwise, it will lead to the flaking off of your pottery glaze.

Happy Sculpting!