If you’ve ever been in the position where you take pottery out of the kiln and it’s got a big old crack in it, you’re not alone. Pottery cracking is a common beginner’s mistake, and while frustrating it can be prevented.

Here, we’ll talk about why your pottery cracks, and what you can do about it. That way, you don’t have to waste more time fixing and recreating pottery.

Cracks Are from Stress

Cracks are usually caused by stress in the clay. There is always some level of stress when it shrinks and gets fired, but the problem is, sometimes it’s too much, and the clay cracks.

The way you make clay also affects stress. For example, if you put an unfired pot on the rim side downwards, a crack will show up later on.

There are different types of stress that can happen with your pots and they are as follows:

-

Stress from being fired at too high of a temperature

-

Stress from the types of corners that are made, such as sharp corners being made to prevent cracking

-

If you dry it too fast, it causes more stress

-

Stress from over-firing a pot or firing it multiple times

-

Stress from cooling it too fast will cause the pottery to crack, possibly shatter as well

These are the common stresses that happen on the pottery when you fire, and usually, these are the common reasons why pottery cracks.

Variations in thickness

Another reason why pottery may stress and crack is because of how thick it is. Thickness variations can cause issues with the stress on the pottery, and if you don’t make sure that it is thick, and even, you’re going to have issues.

Some common variations of thickness include the following:

-

Having a bottom too thin, so the stress is too much

-

Thin areas dry faster than thick, so the stresses won’t be distributed evenly

-

If the base is thicker than the walls, it will show up as a circular edge around the bottom

The solution to this one is pretty simple. If you are making pottery on a wheel, you should make sure the base and walls are even.

If you’re making pottery by hand-building, you should make sure that the walls and base are of the same size, and also blend in the edges as much as you can to prevent any cracks there.

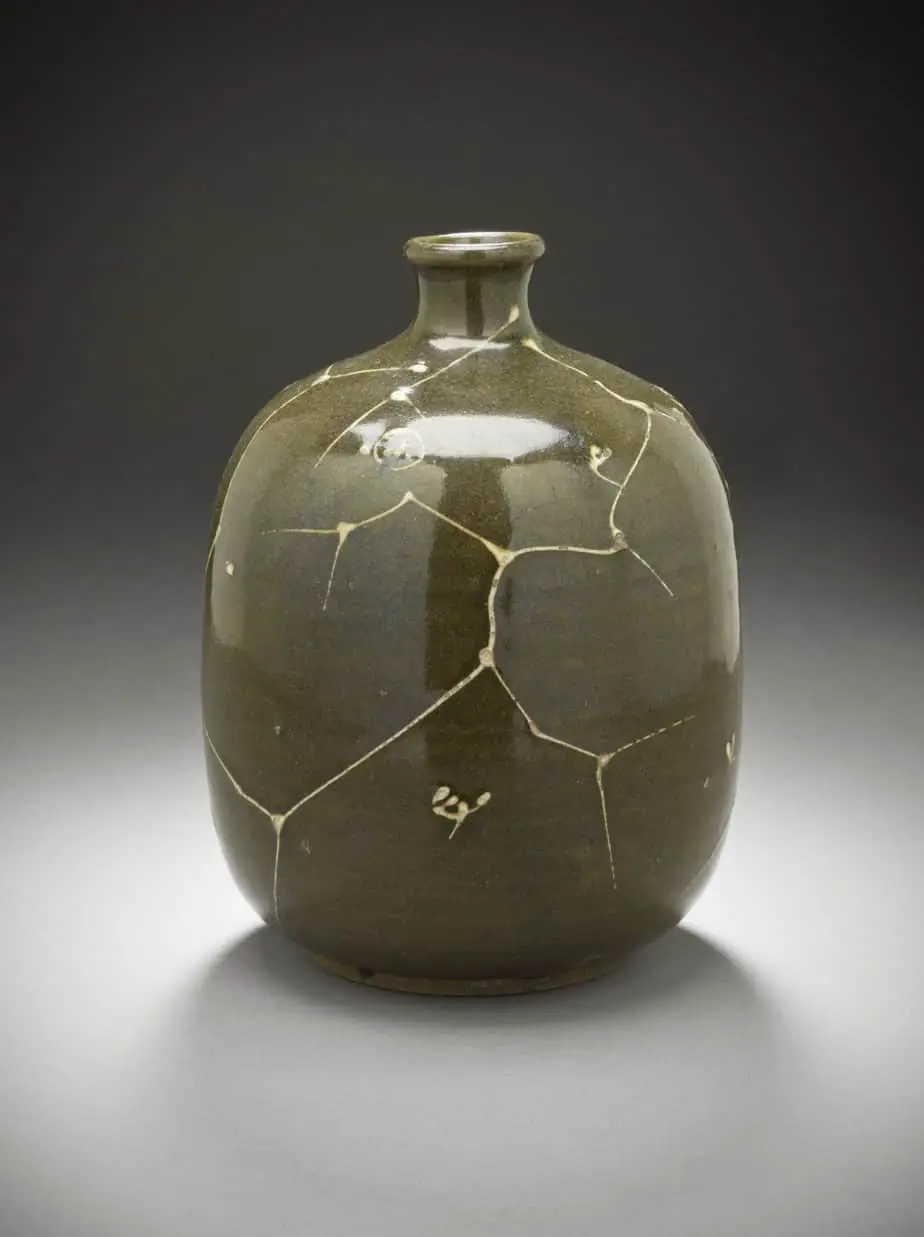

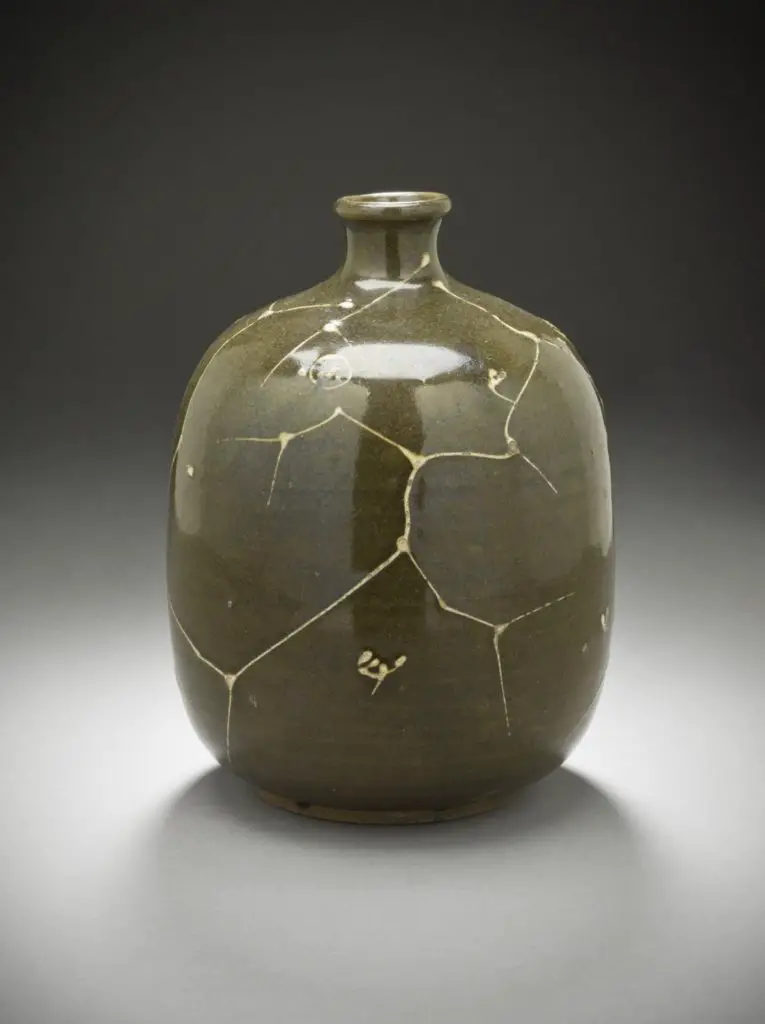

Glazing and Stress

Glaze, while it is something that is encouraged on a piece of pottery, it can also cause stress if misapplied. Glazing causes stress in a different way, and it’s important to understand that.

Some ways glaze causes stress and cracks on the pot include the following:

-

If you use too thick of glaze on the inside, it will stress the outside

-

If there is no glaze on the outside or a thin layer, this causes stress and a spiral crack up each side

-

If there is glaze in the pot, the tension created may cause the pot to crack, or even split

This is why, when you’re applying pottery glaze, you make sure you don’t apply too much on the inside or base and make sure that it’s evenly distributed. If needed, you should clean off the excess before you put this in the kiln to prevent this from happening.

Thermal Shock Fractures and Dunting

These are caused by being too hot, and then suddenly getting too cold. Dunting happens normally during the cooling process, where latent and dormant cracks may even appear.

If there is a crack that appears at any stage, it can get worse if you fire it multiple times, and it can also happen due to thermal expansion.

Dunting is a special type of crack that typically happens. It happens mostly during the two points of silica inversions that happen between 1063 degrees and 439 degrees.

At this point, the silica rearranges, and that’s why it’s important to be mindful of how you fire pottery.

When preventing thermal cooling, you should watch for a few aspects, and they are as follows:

-

Make sure to fire it slowly

-

Make sure to cool this down slowly

-

Remember the top cools faster than the bottom, causing the cracks there

-

If you open the kilns at a temperature of 439, this can cause them to shatter

-

A pot might split in half after three months due to thermal shock

Thermal shock is one that you can prevent if you caused the clay and the glaze to be exposed to different temperature rates, and if the clay is weaker than the object itself, it’ll crack.

How to Fix Cracks

There are a few ways for you to fix cracks, and they’re helpful to understand. If it’s already been fired, you may be out of luck, but here are a few ways to troubleshoot these.

-

Find the widest point of the pot where it’s started to understand what happened

-

If there are cracks at the rim, it began in the raw stage, with the base happening when firing

-

Look at the glaze, if it’s sharp, it happened during firing, and if it’s rounded, it happened early on, and the glazes heated it over

-

From here, you can learn from your lessons, such as making sure the walls are thinned out

-

For thermal shocks, look at your kiln and make sure you can control the temperature easily

-

Always allow for slower firing and cooling of these pieces

Pottery cracks are never fun, and they can be quite an annoyance for beginner potters. But, if you’re sick of having this happen, you need to make sure you understand why your potter cracks, and take time to learn how to fix these mistakes.

It is a common issue with beginner potters, but if you learn from the mistake early on, you can prevent it from happening once again.