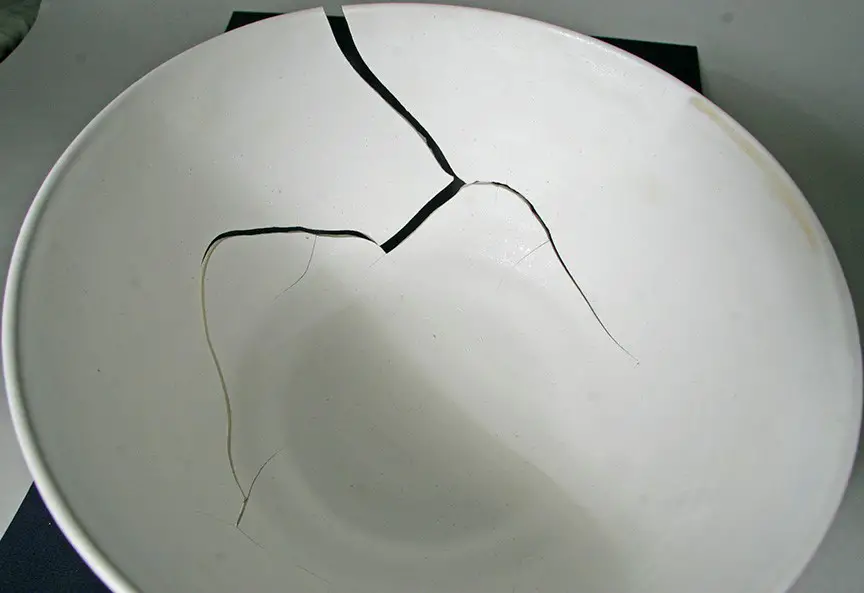

At one point or another, you would have experienced dunting which is in the form of cracking or fracturing in your ceramic pieces. This is something that will make you slightly worried and furious but you should worry no more because help is here. Ha-ha. In this article, I will be discussing what dunting is, how it can be avoided and most importantly, how it can be fixed.

WHAT IS DUNTING?

According to Wikipedia, Dunting is a fault that occurs during the firing of ceramic articles. It is the “cracking that occurs in fired ceramic bodies as a result of a thermally induced stress and it is caused when a ceramic ware cools too quickly after it has been fired. Dunting is cracking associated with a very fast cool-down of the kiln. It often exhibits itself as simple hairline cracks, but ware can fracture into pieces. It is as a result of drawing too soon, from extreme excessive glaze-compression, or low thermal shock-resistance in over vitrified wares resulting from over fluxing.

CAUSES OF DUNTING

Dunting in pottery can also be caused by excessively fast heating rates. “Heating dunts” can be recognized by rounded edges to the cracks as the glaze matured after they occurred, whereas cooling dunts have sharp edges. bodies Ceramic bodies formulated with quartz rather than flint were more susceptible to dunting. clay bodies with high amounts of montmorillonite contain a high percentage of free silica after firing, which may cause the ware to crack during cooling

Dunting or cracks are usually caused by stress in the clay which is a result of how the piece is being fired. There is always some level of stress when it shrinks and gets fired, but the problem is, sometimes it’s too much and the clay cracks.

The way you prepare your clay also affects the level of stress on the piece. For example, if you put an unfired pot on the rim side downwards, a crack will show up later on.

TYPE OF POTTERY STRESS

There are different types of stress that can happen with on pottery and they are as follows:

- Stress from being fired at too high of a temperature

- Stress from the types of corners that are made, such as sharp corners being made to prevent cracking

- Drying a pottery piece too fast

- Stress from firing a pottery piece multiple times

Stress from cooling it too fast will cause dunting on a pottery piece. It can make the ceramic shatter as well.

Stress from cooling it too fast will cause dunting on a pottery piece. It can make the ceramic shatter as well.

Pottery “specialists” proved that dunting happens during the cooling process of a ceramic piece. Latent and dormant cracks may even appear on the “dunted” piece. If there is any crack that appears on the pottery, it will get worse if you fire it multiple times, and it can also happen due to thermal expansion. Dunting is a special type of crack that typically happens. It happens mostly during the two points of silica inversions that happen between 1063 degrees and 439 degrees.

HOW TO TROUBLESHOOT DUNTING ON YOUR POTTERY PIECE?

There are a few ways for you to fix and avoid dunting on pottery, and they are helpful to understand. If already been fired, you may be out of luck, but here are a few ways to troubleshoot these.

- Find the widest point of the ceramic where the crack started to understand what happened: Point out the point where the cracking starts and figure out what happened by checking the rim and base of the pottery piece.

- If there are cracks at the rim of the piece, it began in the raw stage. If the cracks are at the base, it started during the firing process. Cracks on the rim of the piece are as a result of thick and uneven walls while cracks at the base are caused by thermal shocks or firing at very high temperatures. It is advisable to know the type of clay you are firing and not exceed that temperature.

| TYPE OF CLAY | SUMMARY |

| EARTHENWARE | Known as Common clay, it bakes at low temperature and it is used in the making of terracotta pots and pans. |

| MID-FIRE STONEWARE CLAY | Long-lasting, it is usually grey and it bakes at mid temperatures. It is used in the making of jugs, crocks, and dinner-ware. |

| HIGH-FIRE STONEWARE CLAY | Popularly known as Kaolin/China Clay. It is not very plastic and it bakes at very high temperatures. |

- Take a look at the glaze on the piece, if it’s sharp and pointy, it happened during cooling off, and if it’s rounded or smooth, it happened during firing, and then the glazes heated it over.

HOW TO PREVENT DUNTING ON YOUR POTTERY PIECE

- Make sure the walls of the ceramic piece are thinned out properly and evenly: Uneven walls on your pottery piece can cause dunting on the pottery. When molding, you should carefully center your clay and build them up evenly.

- For thermal shocks, look at your kiln and make sure you can control the temperature easily: Thermal shocks are caused when the pottery piece gets too hot, and then suddenly gets too cold. Dunting happens normally during this sudden cooling process.

- Always allow the fired pieces to cool down slowly: Dipping a hot ceramic piece in water immediately after firing can cause serious dunting defects to the body of the piece.

- Get accustomed to your kiln and know how to use it: A lot of dunting effects on pottery pieces are often because of the kiln in which the ware is being fired. Many new digital kilns come with built-in preheat or cool-down programs, but older model digitally controlled kilns don’t have the preheat/cool-down functions. If you use the older versions, you will have to program your firing. If your kiln has a pre-program set-up, you should test the program in a typical firing using self-supporting Orton cones to calibrate the kiln.

Dunting is never fun, and they can be quite annoying for beginner potters. But, if you are tired of having this happen, you need to make sure you understand why your pottery pieces’ crack, then take time to learn how to fix these mistakes.